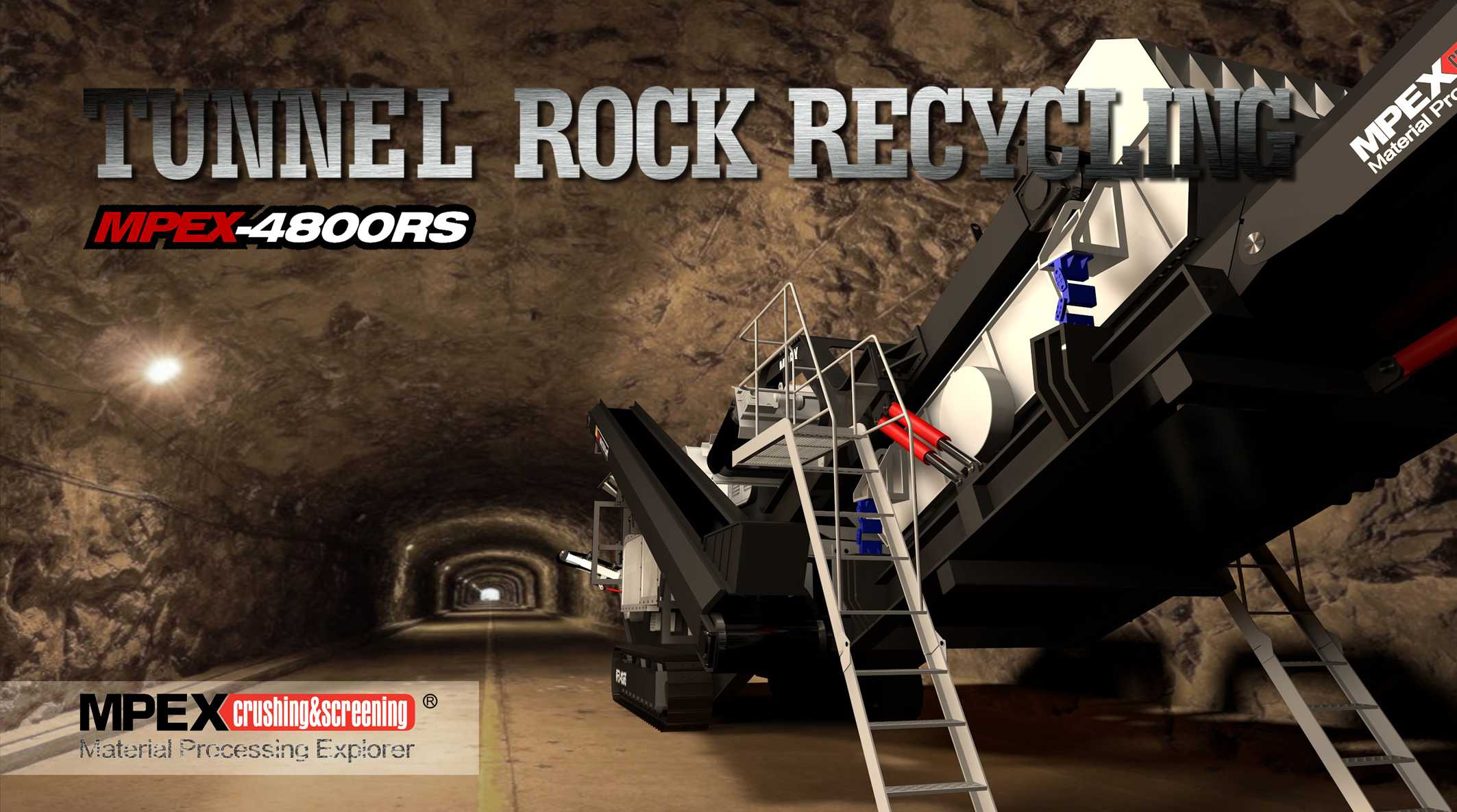

Mobile Crushers and Screeners Play a Major Role in Tunnel Rock Recycling

2021-06-05

689

Tunnel rock recycling is a method to process rock debris from tunneling into other usable needs. The most common is for Concrete aggregates or as Subbase (pavement) for road building. Mobile Crushers and screeners normally used in quarries, have been playing a major role in recycling rock debris at the tunnel site.

In an average tunnel project the excavated rock is mostly regarded as waste. In most cases it is given away or used in a landfill. Excavated rock utilized as concrete aggregate is beneficial both economically and environmentally. It could be of more value generating compared to using the excavated rock as landfill or filling up old quarries. Additionally, the need for transporting aggregate could be significantly reduced as the utilization of the rock could be placed close by a processing facility and a concrete bathing plant. The investment cost of this facility would be repaid in the long run as the project would be close to self-supplied in construction aggregates.

There are two main types of tunneling, Drill & Blast(D&B) and Tunnel Boring Machine (TBM) and both methods allow for recycling, if rock quality is approved. Both methods require some sort of processing. TBM creates rock particles with excessive amounts of fines, this is a problem for both subbase and concrete aggregate, max diameter of particles is approximately 170 mm. When it comes to D&B the particles can get up to 800 mm and there is a much coarser fraction, too large for subbase and concrete aggregate. The processing facility has the following choices to edit the rock mass: reduce rock size, remove fines and reduce moisture content.

Crushing

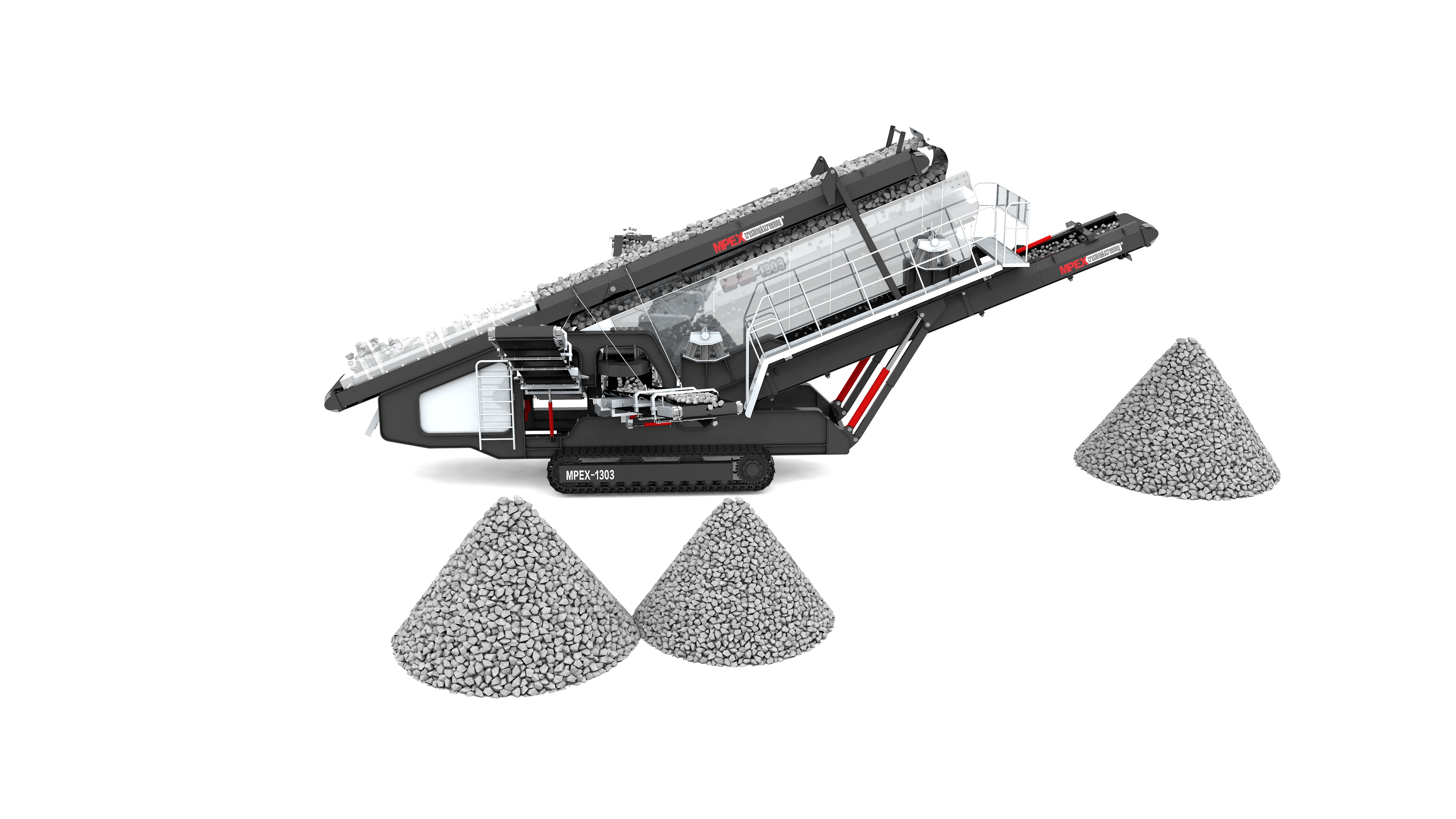

The main role in processing tunnel rock is crushing the rocks into smaller sizes. Rock crushing is divided into two methods based on compression or impact resulting in different type of fragmentation of the material. Mobile crushersmeet the highest specifications for mobility and versatility, both on-site and on-road.Easy transport without any special permits allows rapid movement between jobs. The on-board dust suppression system keeps dust emissions to a minimum. Setup time from unload to crush is less than 20 minutes. For cubification of the rock, the tracked mobile impactor is a suitable crusher. The technology lets the rocks collide with each other and split at the natural cleavage lines. This is favorable for both subbase and concrete aggregate. This new generation tracked mobile impactor with redefined style and advanced technological design gives improved material flow and production capabilities in recycling applications. Incorporating the impact chamber with direct drive and advanced electronic control system the machine provides operators with high material reduction ratios and produces a consistent product shape. A key component of the machine is the on-board innovative quick detach two-deck screen. For applications not requiring recirculation of materials for further processing or stockpiling the complete screening and recirculating system can be quickly detached from the machine. The high productivity, ease of maintenance and operation makes the machine an ideal solution for large scale producers and contract crushing operators.

Features

The ease of material flow through the machine has greatly improved with each component of the machine increasing in width as the material moves through the machine.

Heavy duty vibrating feeder (VGF) with integrated prescreen removes dirt fines and sizes bypass material for reprocessing.

Quick on-board detachable recirculating system including large two deck screen.

Recirculating conveyor can be rotated from closed loop configuration or utilized for stockpiling making an additional oversized product.

Screening

In Tunnel boring machine(TBM) tunneling mechanical screening (scalping screener) is normally the first stage of the processing of tunnel rock. The screener removes rock particles below 16 or 20 mm diameter.This is to remove the high amounts of fines which is created when TBM tunneling in hard rock. Too much fines in concrete aggregates is unwanted. Tracked mobile screener is aeasily transportable machine thatoffers operators rapid set up and tear down times. The NEW screenbox features three large inclined screens giving a large screening areato provide efficient screening and high capacity. The screenbox featuresquick wedge tensioning, access holes and bottom deck hydraulic tensioning system to reduce time required for mesh changes. All four discharge conveyors are adjustable and hydraulically fold for transport. Thefourth product ‘oversize plus’ conveyor has variable tilt and side slew to accurately discharge material for recirculation and stockpiling.

Features

The fourth (oversize plus) conveyor provides variable tilt and slide slew capability to accurately discharge materials for recirculation to crushers or for stockpiling.

Maximum utilization of three decks provides ultra-efficient screening capabilities even at small aggregate sizes.

A combination of quick wedge tensioning, convenient access holes and hydraulic tensioning on the bottom deck ensure mesh set up and change out times are kept to an absolute minimum.

Creating concrete with recycled aggregates

Recycling rock to produce concrete aggregate is a complex procedure and will require an on-site laboratory at the tunnel project. Concrete aggregate has strict requirement which must be tested, this can in some

cases require between 5-15 different laboratory tests, regarding mechanical strength, grading and impurities.

The requirements of the aggregate from tunnel rock is tested and measured on the same level as concrete aggregate from quarries.

Previous

Next